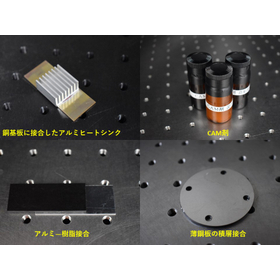

[Case Study Presentation] CAM Joining Enabled Dissimilar Material Bonding with Low Thermal Resistance

The bonding strength is secured at over 10 MPa in shear tension! It is possible to join dissimilar materials such as metals, resins, and ceramics, which is essential for improving heat dissipation characteristics.

Our company conducts trial processing, specialized CAM agents, and process development using CAM bonding technology. This bonding technology combines chemical bonding and fusion. It is environmentally friendly, allows for easy construction, and can reduce costs. CAM agents are applied and dried on metal surfaces to form an organic film, which bonds the joined materials through thermal pressing. You can read technical documents that describe detailed features and functions. 【Examples of bondable materials】 ■ Metals: Aluminum, Copper, Steel, Titanium ■ Resins: Nylon, PBT, CFRP ■ Ceramics: Alumina, Glass ■ Zero thermal resistance is also possible.

- Company:輝創 輝創株式会社

- Price:Other

![[Case Study Presentation] CAM Joining Enabled Dissimilar Material Bonding with Low Thermal Resistance](https://image.mono.ipros.com/public/product/image/146/2001502278/IPROS11074528976109451525.png?w=280&h=280)